James' 92 RZ build

- Thread starter JamesP

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I can see where you guys are coming from. I think the fact I bought it being told it needs a rebuild is giving me the dreaded rotary paranoia. Although there seems to be a few issues with it, which is not helping my paranoia. It really doesn't like to start hot or cold. I have to hold it on the starter for what seems like a very long time before it slowly coughs into life. I know rotaries can turn over a bit before starting but it really doesn't want to start. Now I have to top up the coolant after every drive with there being no signs of any leaks. I will do another champagne test now it's using a lot of coolant to see what's going on.

I just think pulling the engine gives me a chance to go over everything and finally get the car running properly. I want to do a few bits and tidy up the engine bay as well.

Just get a comp test done to start with mate and go from there! £40-50 and you know if it’s in the 4’s then fair enough but really 6 or 7’s then why rebuild?!..

jdmr_neil

Well-known member

- Location

- Northumberland

Compression usually shows itself in hot starting because of expansion. With a cold engine it should fire into life. Slow starting could be Lots of things from fuelling to ignition.

A good service with fuel filter and plugs would be worthwhile if not already.

A good service with fuel filter and plugs would be worthwhile if not already.

Fiddy

Serial time waster

- Location

- Isle of Wight

If you need to free up some cash for a rebuild I would buy those horrid seats off you for a few hundred

Compression usually shows itself in hot starting because of expansion. With a cold engine it should fire into life. Slow starting could be Lots of things from fuelling to ignition.

A good service with fuel filter and plugs would be worthwhile if not already.

It's had a full service recently, including new fuel filter, plugs and leads. I've covered all the bases to try and solve the issues but the car never seems to improve much. I'm going to investigate the coolant issues next before I go ahead and open the engine up but to me things seem to be pointing to coolant seals giving up.

If you need to free up some cash for a rebuild I would buy those horrid seats off you for a few hundred

Haha the cash would be helpful but the last thing I'm selling is the seats

Well champagne test confirmed water seal issues. Contestant stream of bubbles through filler neck.

So the car is now in my unit over the pit so I can pull the engine out. Started stripping everything off so I can get the engine out. Hopefully be out and apart in the next week or two if all goes too plan.

So the car is now in my unit over the pit so I can pull the engine out. Started stripping everything off so I can get the engine out. Hopefully be out and apart in the next week or two if all goes too plan.

At least it's just soft seals that are gone! At least it's not alot as mucharging to fork out as a full rebuild or even smashed in rotors and housings

Don't forget your 54mm socket on the flywheel side

Yeah hopefully it's been caught early and only needs more of a refresh than a full on rebuild.

Haha not looking forward to getting that one off!

Yeah I put the windows up before I started work. Got a cover on the car as well as the unit it's in is an absolute mess.Put your windows up, its amazing the dust and crap that gets in there over a period of time

Managed to get the engine out yesterday. It was easier than I thought it would be. Took the engine home ready to start stripping it down.

Started stripping everything off the block. Got the turbos off and had a look in the housings. Front housing is very wet so looks like it definitely was water seal failure. Now waiting on a engine stand to be delivered this week so I can get it mounted ready to get the engine completely stripped and opened up.

Started stripping everything off the block. Got the turbos off and had a look in the housings. Front housing is very wet so looks like it definitely was water seal failure. Now waiting on a engine stand to be delivered this week so I can get it mounted ready to get the engine completely stripped and opened up.

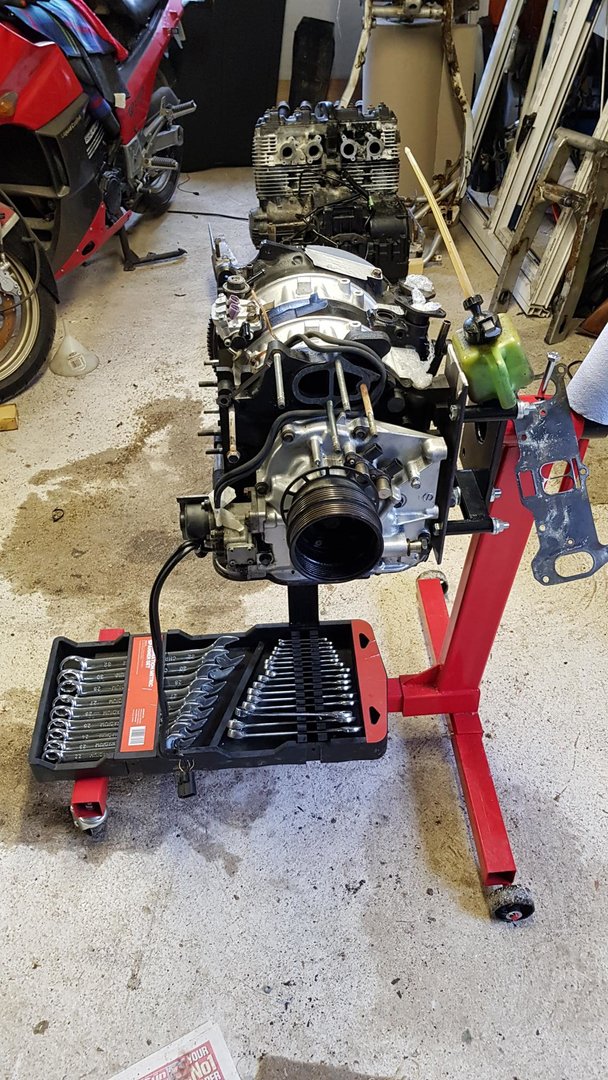

Got the engine stripped down to a bare block in a few evenings.

Got it mounted on the engine stand and finally got it opened up.

Then ended up with this massive mess.

Overall everything was in ok condition. No nasty marks or scoring on the housings or irons. Rotors were all good. All seals were still intact so nothing major had happened but the water seals had gone very hard and brittle. Definitely leaking on the front rotor. Just starting to mark the front iron where it obviously had water sitting in the bottom of the housing. That can be seen on the photo.

Started looking into getting a rebuild kit and what the best option was to take at this stage. After to speaking to tim at RX Motors he offered to build the engine back up for me for what I thought was a very reasonable price. So I dropped everything up to him on Thursday and he's hoping to get it back together in a couple of weeks. Gone for mazda parts on everything but he advised rotary aviation apex seals as there a bit stronger and the car has been running very lean. He said they will hold up better if the car isn't running 100% on the first start up. Need to work out what's causing the lean running next as I don't fancy starting it back up with the chance of any major issues. I'll update once the engine comes back.

Got it mounted on the engine stand and finally got it opened up.

Then ended up with this massive mess.

Overall everything was in ok condition. No nasty marks or scoring on the housings or irons. Rotors were all good. All seals were still intact so nothing major had happened but the water seals had gone very hard and brittle. Definitely leaking on the front rotor. Just starting to mark the front iron where it obviously had water sitting in the bottom of the housing. That can be seen on the photo.

Started looking into getting a rebuild kit and what the best option was to take at this stage. After to speaking to tim at RX Motors he offered to build the engine back up for me for what I thought was a very reasonable price. So I dropped everything up to him on Thursday and he's hoping to get it back together in a couple of weeks. Gone for mazda parts on everything but he advised rotary aviation apex seals as there a bit stronger and the car has been running very lean. He said they will hold up better if the car isn't running 100% on the first start up. Need to work out what's causing the lean running next as I don't fancy starting it back up with the chance of any major issues. I'll update once the engine comes back.

Good work buddy! This your first engine strip down?

Did you just use a piece of plate metal on the engine stand t make an adaptor?

It's my first rotary strip down. Done a few piston engines before.

Yeah just a strip of 6mm steel plate. Could have done with spacing it off a bit though. I couldn't spin the engine in a full rotation on the stand as it just caught the stand when spun upside down but didn't cause any issues.

Whilst waiting on the block to be Built, I've been getting everything ready to go back on as soon as I get the engine back.

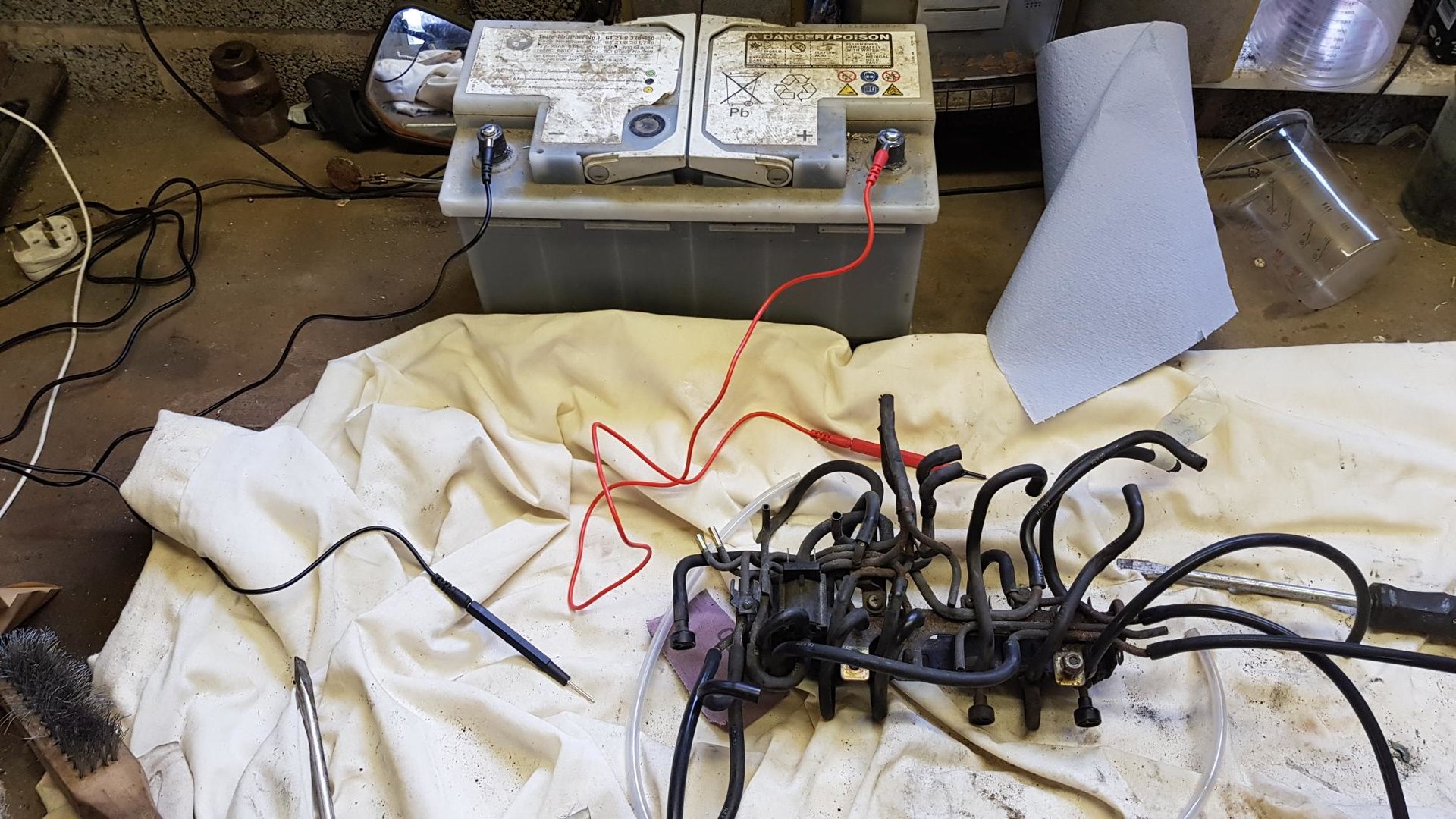

Set up a battery and tested all the solenoids. Turned out the turbo vacuum and the purge control ones weren't working at all. Also one in the solenoid rack had the nipple snapped off and instead of someone replacing it they just blocked of the open hose. That would explain a hose I had that just had a bolt screwed in the end and I couldn't find a home for it when I looked previously.

I will be replacing all the hoses with silicone and fitting new check valves before it goes back on the engine.

Tested the wastegate and pre control actuators as well, all working fine. Did find the hoses on them to be very tired and one had split so they will get replaced as well. Finding a few problems like this is good news though, shows why the car was never running 100% and now I can get it all sorted before the engine goes back in the car.

Next up was giving everything a clean. I'm sending a few bits off to be vapour blasted the freshen them up. Just washed everything with degreaser and wire brush. Surprising how much better they came up with very little effort.

Got a list of parts to order up and hopefully get the engine back this week. Then soon start reassembly.

Set up a battery and tested all the solenoids. Turned out the turbo vacuum and the purge control ones weren't working at all. Also one in the solenoid rack had the nipple snapped off and instead of someone replacing it they just blocked of the open hose. That would explain a hose I had that just had a bolt screwed in the end and I couldn't find a home for it when I looked previously.

I will be replacing all the hoses with silicone and fitting new check valves before it goes back on the engine.

Tested the wastegate and pre control actuators as well, all working fine. Did find the hoses on them to be very tired and one had split so they will get replaced as well. Finding a few problems like this is good news though, shows why the car was never running 100% and now I can get it all sorted before the engine goes back in the car.

Next up was giving everything a clean. I'm sending a few bits off to be vapour blasted the freshen them up. Just washed everything with degreaser and wire brush. Surprising how much better they came up with very little effort.

Got a list of parts to order up and hopefully get the engine back this week. Then soon start reassembly.

Got the engine back from RX Motors this week. Got it mounted up on the stand ready to build back up. Waiting on a few bits so I can get everything back on. Hopefully be ready to drop back in the car in a couple of weeks.

Also had a load of parts vapour blasted. Not sure I'm I like how the finish has come up, I may get them polished in the future but they'll do for now.

Also had a load of parts vapour blasted. Not sure I'm I like how the finish has come up, I may get them polished in the future but they'll do for now.

That rebuild was quick mate! What porting of any was done on the block?!

The finish looks good! Worse case just wrinkle black it if you don’t like it

Yeah it was with tim @ RX Motors for 3 weeks. Including him waiting for apex seals to come from America. He got it built fairly quick. He reckons he build 3 engines a week. No porting. It's staying fairly standard on stock twins so didn't see the need to have any porting done. Not going to be hunting any big power figures with it.

It's bad as such, just can see how rough the original casting of the parts is. I'll see how it looks when it's all back together as a lot of it can't really be seen when it's in the bay.

Finally got everything to get the engine back together. Spent the weekend getting everything back on the block. Few little things to finish off but 95% finished now.

Went from this:

Halfway there:

To the current state:

Spent a fair bit of time going over the rats nest, replaced most of the hoses with silicone tube and put on new check valves. All the solenoids have been tested so everything should be working perfectly. Next up is tidying up the engine bay. I'll degrease and clean everything. Paint any brackets the are on show as there looking a bit messy. Then drop the engine back in.

Went from this:

Halfway there:

To the current state:

Spent a fair bit of time going over the rats nest, replaced most of the hoses with silicone tube and put on new check valves. All the solenoids have been tested so everything should be working perfectly. Next up is tidying up the engine bay. I'll degrease and clean everything. Paint any brackets the are on show as there looking a bit messy. Then drop the engine back in.